Basic Info.

Model NO.

BTH-SERIES

Temperature Deviation

≤2.0ºC

Emperature Uniformity

≤±2.0ºC

Master Keyword

Climatic Test Chamber Price

Primary Keyword

Climatic Test Chamber Manufacturers

Keyword

Climatic Test Chamber Factory

Transport Package

Each Set Protected with Resin Fiber and PP Film, T

Specification

Test Space 500x600x500(customizable)

Trademark

DGBELL

Origin

Guangdong China

HS Code

8479899990

Production Capacity

100set /Month

Product Description

DGBELL Temperature and Humidity Environmental Climate Test Room

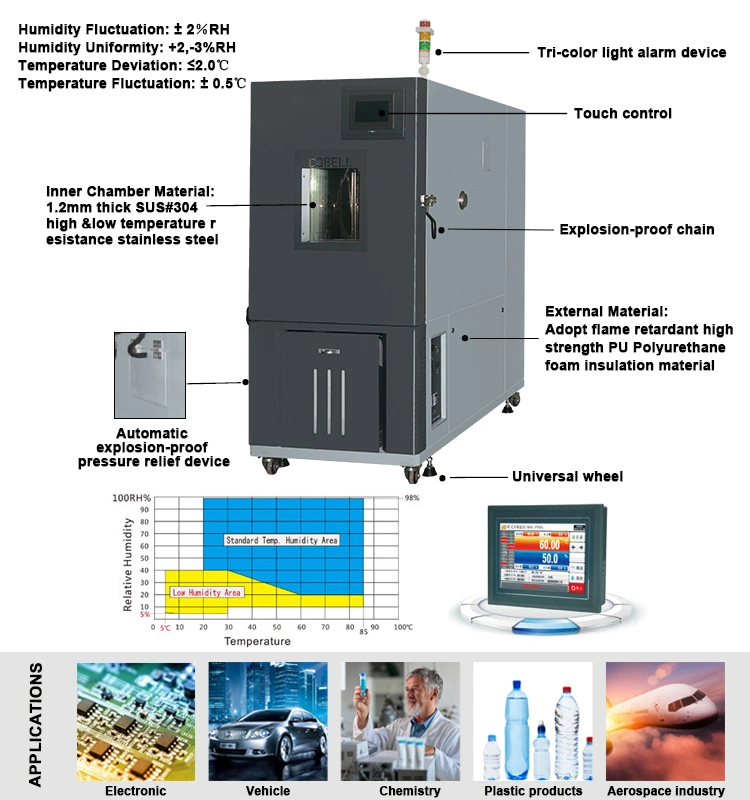

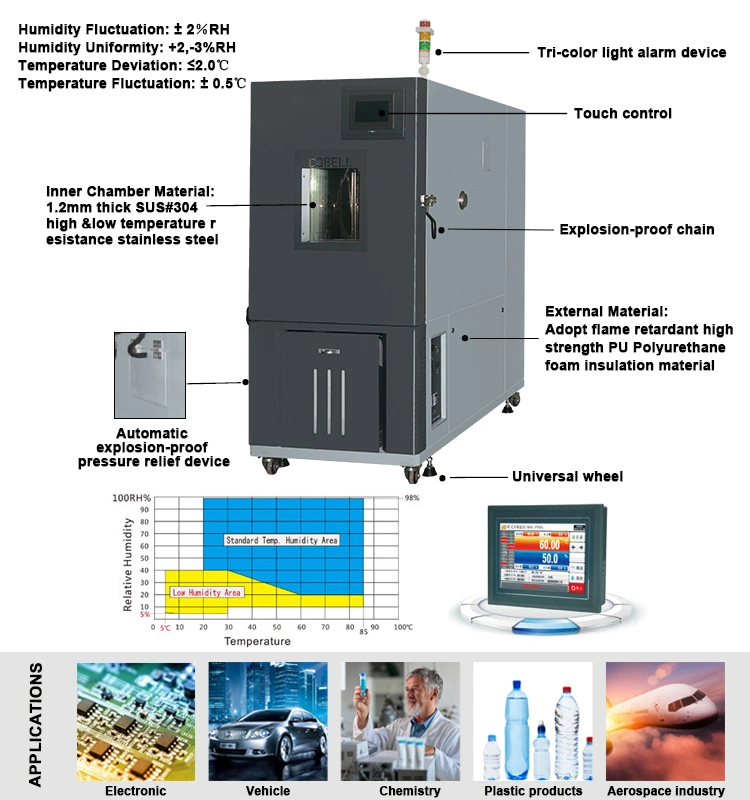

Product show

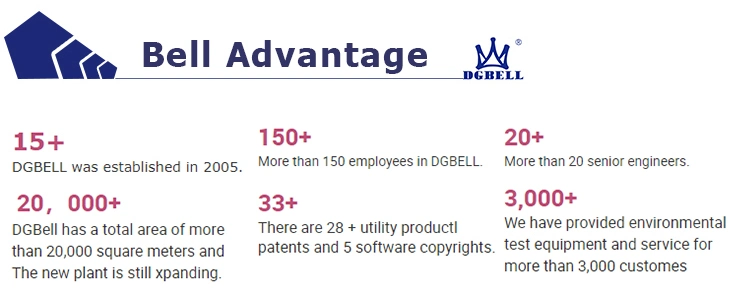

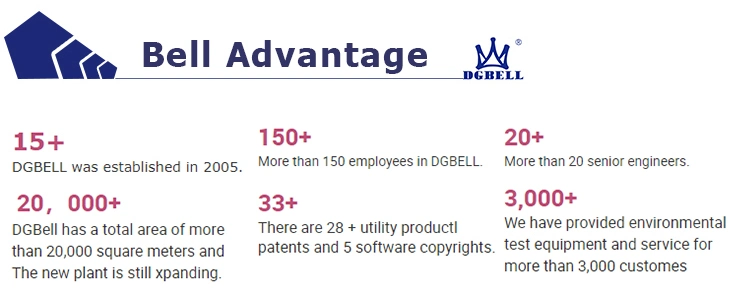

Established in 2005, Guangdong Bell Experiment Equipment Co., Ltd is specialized in manufacturing a variety of quality inspection instruments, testing equipments and other high-tech products which mainly include: Constant Temperature & Humidity Test Chamber,High & Low Temperature Test Chamber, High & low Temperature Testers with Rapid Temperature Change, Walk-In humidity & temperature test chamber, Cool/Thermal shock test chamber, Salt spray chamber, High temperature aging tester, sand and dust testing machine,tension tester, high and low temperature testing machine , servo computer battery crush tester, mechanical vibration testerBattery washing tester ,battery burning tester and other quality testing instruments. Thanks to several decades of R&D efforts,the company has established itself as a leading provider of testing instruments of the industry, playing a crucial role in the research and development of high-quality and high-value products within the industry.

15+ years experience in test chambers manufacturing, High performance for your projects.

With unmatched quality advantage, a dynamic management team, professional customer services, superb manufacturing techniques and innovative research and development ideas, Guangdong Bell Experiment Equipment Co., Ltd, supported by an international, standard and professional quality policy, is gradually becoming an international brand. Its products are manufactured in consistent with a number of world standards.

Product show

Application

Rapid Rate Temperature Cycle Test Chamber is developed and manufactured to match the ESS (Environment Stress Screen) test. It is an ideal reliability testing and validation equipment to find out the product failure with high accelerate environment condition. Our test chambers help you to make safe and reliable products before delivering to the people who use them.

Feature

- Test Cabinet made by Seal Welding SUS #304 Stainless Steel.

- Introducing Japanese and German technology for the Refrigerating System, energy saving more than 20%.

- Fire Resistant High Strength PU Foam Insulation Material.

- Temperature Ramp Rate: 5°C / 10°C / 15°C per minute (Linear or Non-Linear controllable).

- Optional Function: Fume Exhaust System, Explosion-proof System.

Standard Compliance

- IEC60068-2-1:2007 (GB/T2423.1-2008) Environmental testing - Part 2: Test methods - Tests A: Cold

- IEC60068-2-2:2007 (GB/T2423.2-2008) Environmental testing for electric and electronic products Test methods - Tests B:Dry Heat

- IEC 60068-2-14 2009 Environmental testing - Part 2-14: Tests -Test N: Change of temperature

Performance parameters

| Model | BTKS-150 | BTKS-225 | BTKS-408 | BTKS-800 | BTKS-1000 |

|---|---|---|---|---|---|

| Test Space | 500x600x500 | 500x750x600 | 600x850x800 | 1000x1000x800 | 1000x1000x1000 |

| W x H x D (mm) | |||||

| External Dimension | 700x1700x1370 | 700x1750x1420 | 650x1650x1270 | 1200x1900x1620 | 1200x1900x1820 |

| W x H x D (mm) | |||||

| Temperature Range | -70~150ºC | ||||

| Temperature Fluctuation | ±0.5ºC | ||||

| Temperature Deviation | ≤2.0ºC | ||||

| Temperature Uniformity | ≤±2.0ºC | ||||

| Heating Rate | From -40ºC to 80ºC,full range non-linear average about5ºC/min(10ºC/min or15ºC/min can be customized) ,no load. | ||||

| Cooling Rate | From 80ºCto -40ºC ,full range non-linear average about5ºC/min(10ºC/min or15ºC/min can be customized),no load | ||||

| Temperature Overshoot | ≤±2ºC | ||||

| Internal Material | 1.2mm thick SUS#304 high &low temperature resistance stainless steel. | ||||

| External Material | Adopt flame retardant high strength PU Polyurethane foam insulation material. | ||||

| Control Method | Touch screen programmable PLC, with USB interface, with RJ485 interface can be connected to computer controlling, special network control software, convenient remote monitoring, data acquisitioning. | ||||

| Compressor | Tecumseh (France)-fully air-cooled double-fall cooling compressor. Or Bock (Germany) semi-enclosed air-cooled refrigeration. | ||||

| Safety Protection | Explosion-proof pressure relief device, explosion-proof chain, mobile phone alarm device, networking, smoke exhaust device, fire extinguishing device, etc. | ||||

Established in 2005, Guangdong Bell Experiment Equipment Co., Ltd is specialized in manufacturing a variety of quality inspection instruments, testing equipments and other high-tech products which mainly include: Constant Temperature & Humidity Test Chamber,High & Low Temperature Test Chamber, High & low Temperature Testers with Rapid Temperature Change, Walk-In humidity & temperature test chamber, Cool/Thermal shock test chamber, Salt spray chamber, High temperature aging tester, sand and dust testing machine,tension tester, high and low temperature testing machine , servo computer battery crush tester, mechanical vibration testerBattery washing tester ,battery burning tester and other quality testing instruments. Thanks to several decades of R&D efforts,the company has established itself as a leading provider of testing instruments of the industry, playing a crucial role in the research and development of high-quality and high-value products within the industry.

15+ years experience in test chambers manufacturing, High performance for your projects.

With unmatched quality advantage, a dynamic management team, professional customer services, superb manufacturing techniques and innovative research and development ideas, Guangdong Bell Experiment Equipment Co., Ltd, supported by an international, standard and professional quality policy, is gradually becoming an international brand. Its products are manufactured in consistent with a number of world standards.

Complete QC inspection process,Guarantee high quality of each machine.

1. IQC Incoming Quslity Control

1. IQC Incoming Quslity Control

2. IPQC InPut Process Quality Control

3. FQC Final Quality Control

4. OQC Outgong Quality Control

Our service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual.

Onsite Service:

1.Device installation;

Free information:

1.Product Instruction;

2.Product operation instruction/video;

3.Experiment Test (test application, test report)

Device Problem Handling:

1.Social media 24 hours online communication;

2.Email contact;

3.Video Conferencing;

3. FQC Final Quality Control

4. OQC Outgong Quality Control

Our service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual.

Onsite Service:

1.Device installation;

2.Equipment Operation Test Technology training;

3.Equipment Calibration;

4.Daily maintenance and maintenance of equipment Free technical training for visiting factories 24-hour Online contact Free software upgrades

3.Equipment Calibration;

4.Daily maintenance and maintenance of equipment Free technical training for visiting factories 24-hour Online contact Free software upgrades

Free information:

1.Product Instruction;

2.Product operation instruction/video;

3.Experiment Test (test application, test report)

Device Problem Handling:

1.Social media 24 hours online communication;

2.Email contact;

3.Video Conferencing;