Basic Info.

Model NO.

Sanhe-HC

Structure Material

Honeycomb Ceramic

Cell Density (In2)

100-400 Holes

Bulk Density (g/cm3)

0.45~0.50

Organic Adsorption Capacity

>2%

Purification Efficiency

90~95%

Service Life

> 3 Years

Customization

Yes

Transport Package

Pallet

Specification

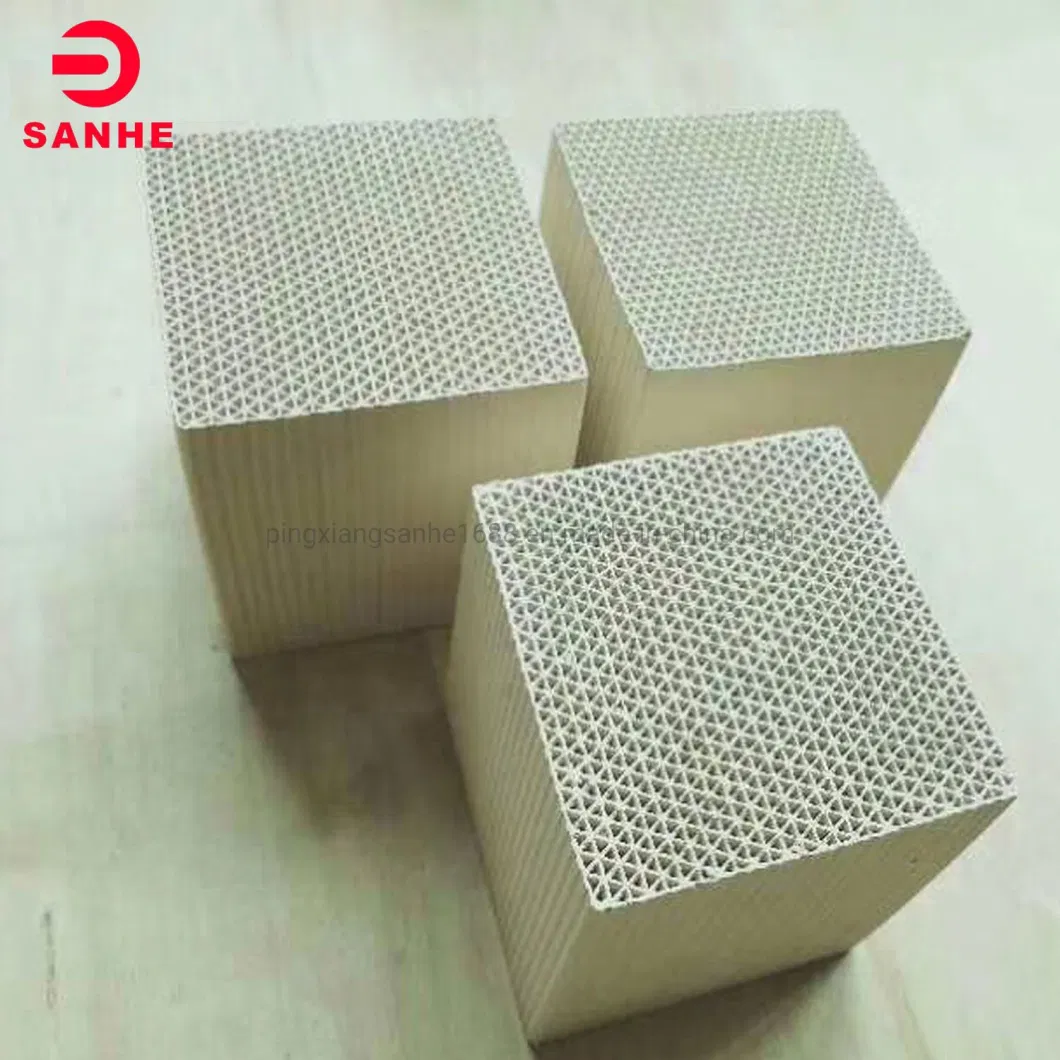

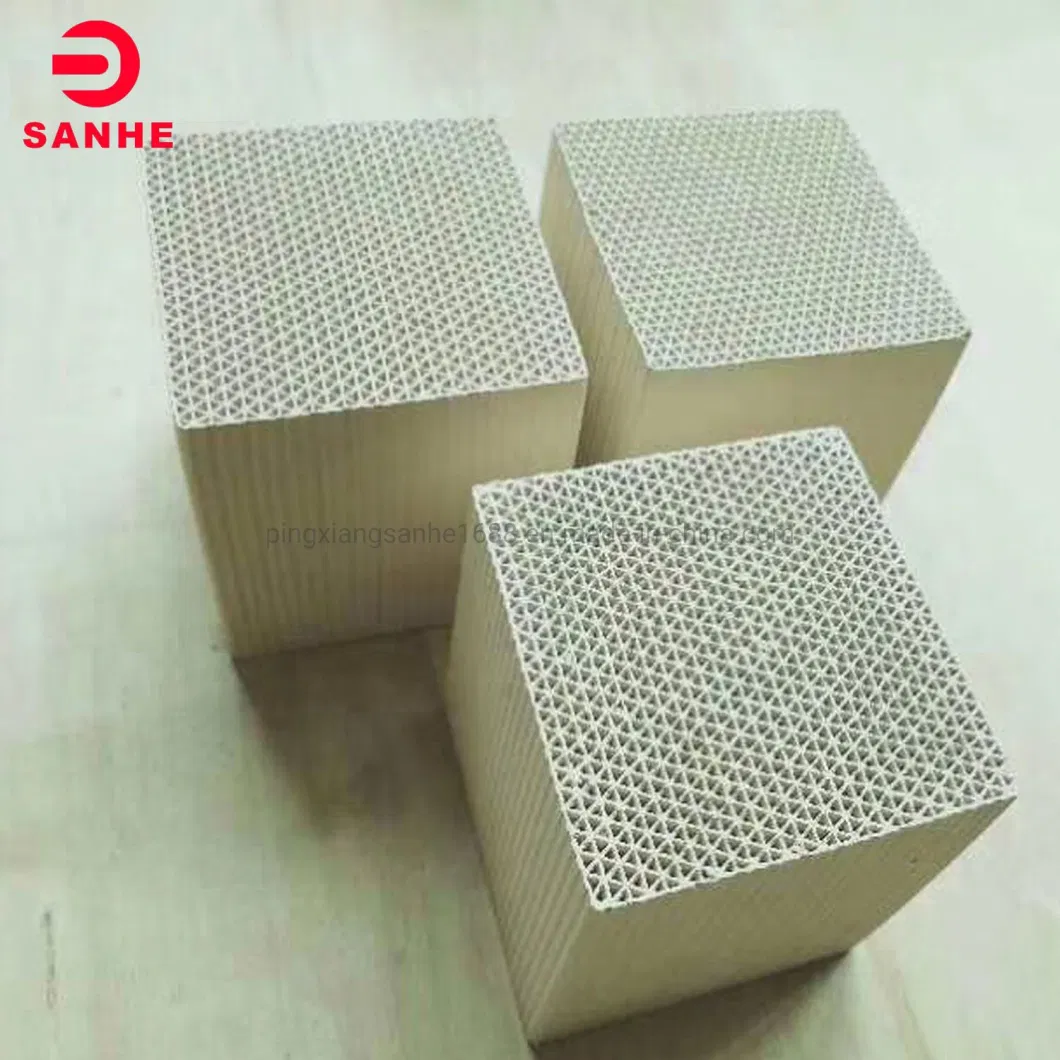

100x100x50mm, 100x100x100mm, etc

Origin

China

HS Code

3824999990

Production Capacity

50000PCS/Month

Product Description

VOCs Purification - Hydrophobic Zeolite Molecular Sieve

Our company has designed and produced hydrophobic molecular sieves for waste gas treatment in close cooperation with the Institute of Physics and Chemistry of Chinese Academy of Sciences. This product uses an adsorption system to increase the concentration of exhaust gas and reduce the air volume. At the same time, it combines with catalytic combustion technology to reduce operation costs.

*Name: VOCs Environmentally Friendly Adsorbent

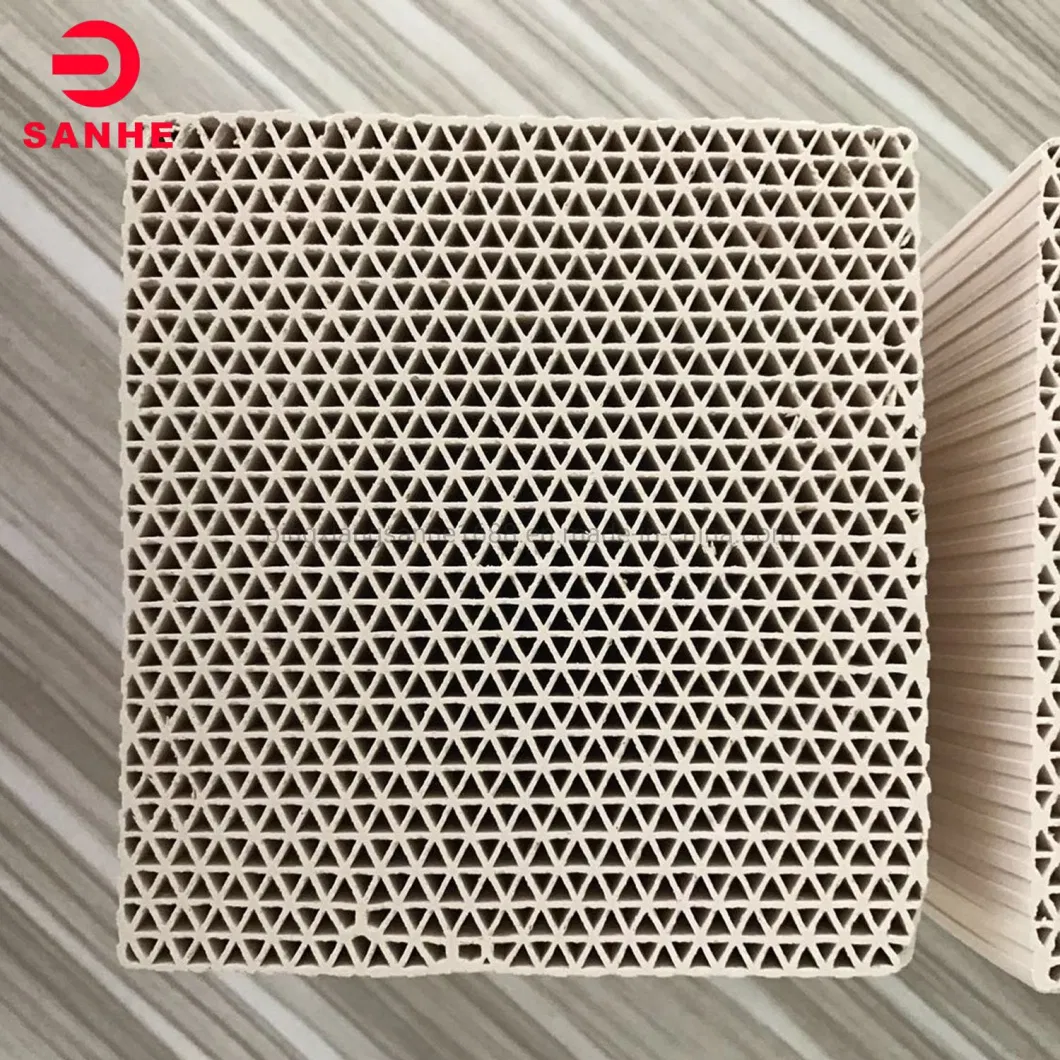

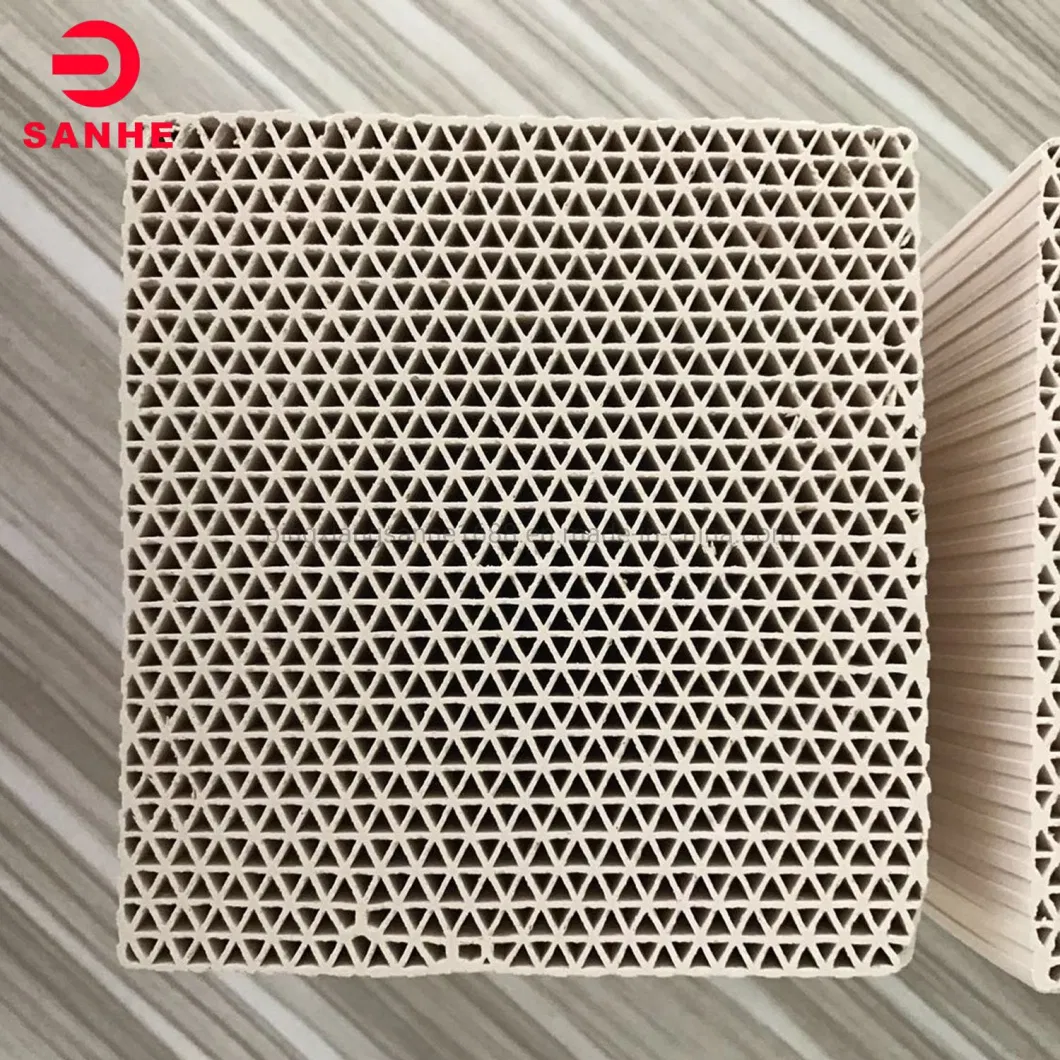

*Shape: Honeycomb *Cell Density (in2): 100-400 Cells

*Bulk Density (g/cm3): 0.45-0.50 *Source: synthetic zeolite

*Spec: 100*100*100mm *Package: sealed and packed in cartons

*Typical airspeed: 6000-10000h -1 *Manufacturer: Pingxiang Sanhe Ceramics CO., LTD.

Application introduction

At present, VOCs treatment mainly adopts activated carbon, which cannot be desorption at high temperature, so it is replaced regularly. Moreover, activated carbon which adsorbs organic matter is a dangerous chemical, so the treatment cost is high.Our environmentally friendly adsorption material is a hydrophobic molecular sieve, which is different from the ordinary molecular sieve in the preferential adsorption of water in the gas, it has a high selective adsorption capacity for organic matter, and disintegrate under high temperature, so as to achieve continuous adsorption - regeneration.The adsorption material adopts a special preparation process to make a monolithic honeycomb, with an adsorption efficiency of >90% on organic matter, and can be adsorbed and regenerated for a long time.

Features:

* High temperature regeneration, high efficiency, high safety, large adsorption capacity, strong adsorption capacity and adsorbability;

* A substitute for honeycomb activated carbon, can be desorption at high temperature and desorption thoroughly;

* Used in organic waste gas adsorption, catalyst loading, acid catalysis, catalytic oxidation and other fields, including furniture coating, automobile paint spraying, ship, electronics industry, etc.;

* According to different organic waste gas, different zeolite molecular sieves are configured, and technical solutions are provided to select the most suitable products for customers;

* Product size can be customized according to customer requirements.

The honeycomb zeolite zeolite which produced by Sanhe Group has the following advantages:

1. Strong adsorption selectivity: According to different components of organic waste gas, the products are equipped with molecular sieve materials with different properties and pore size, so as to achieve targeted and selective treatment of organic waste gas, meet the design requirements and emission standards.

2. Strong adsorption capacity: Even if the composition concentration of the gas is very low at mg level, it still has adsorption capacity.Compared with similar activated carbon to improve the efficiency of 50%.

3. Wide adaptability of adsorption temperature: The adsorption capacity of zeolites is still relatively high even at higher temperature, while other adsorbents are greatly affected by temperature. Therefore, the adsorption capacity of zeolite is large at the same temperature.

4. Good regenerative temperature resistance: After adsorption and concentration by molecular sieve, the concentration factor of pollutants can be up to 15 times to 20 times. After concentration, the waste gas can be condensed and recycled or processed by high temperature combustion as required.

5. High strength: Using special skeleton materials, so that the honeycomb zeolite positive compressive strength can be more than 3Mpa, to reduce damage during transportation and installation.

Technical Index:

Our company has designed and produced hydrophobic molecular sieves for waste gas treatment in close cooperation with the Institute of Physics and Chemistry of Chinese Academy of Sciences. This product uses an adsorption system to increase the concentration of exhaust gas and reduce the air volume. At the same time, it combines with catalytic combustion technology to reduce operation costs.

*Name: VOCs Environmentally Friendly Adsorbent

*Shape: Honeycomb *Cell Density (in2): 100-400 Cells

*Bulk Density (g/cm3): 0.45-0.50 *Source: synthetic zeolite

*Spec: 100*100*100mm *Package: sealed and packed in cartons

*Typical airspeed: 6000-10000h -1 *Manufacturer: Pingxiang Sanhe Ceramics CO., LTD.

Application introduction

At present, VOCs treatment mainly adopts activated carbon, which cannot be desorption at high temperature, so it is replaced regularly. Moreover, activated carbon which adsorbs organic matter is a dangerous chemical, so the treatment cost is high.Our environmentally friendly adsorption material is a hydrophobic molecular sieve, which is different from the ordinary molecular sieve in the preferential adsorption of water in the gas, it has a high selective adsorption capacity for organic matter, and disintegrate under high temperature, so as to achieve continuous adsorption - regeneration.The adsorption material adopts a special preparation process to make a monolithic honeycomb, with an adsorption efficiency of >90% on organic matter, and can be adsorbed and regenerated for a long time.

Features:

* High temperature regeneration, high efficiency, high safety, large adsorption capacity, strong adsorption capacity and adsorbability;

* A substitute for honeycomb activated carbon, can be desorption at high temperature and desorption thoroughly;

* Used in organic waste gas adsorption, catalyst loading, acid catalysis, catalytic oxidation and other fields, including furniture coating, automobile paint spraying, ship, electronics industry, etc.;

* According to different organic waste gas, different zeolite molecular sieves are configured, and technical solutions are provided to select the most suitable products for customers;

* Product size can be customized according to customer requirements.

The honeycomb zeolite zeolite which produced by Sanhe Group has the following advantages:

1. Strong adsorption selectivity: According to different components of organic waste gas, the products are equipped with molecular sieve materials with different properties and pore size, so as to achieve targeted and selective treatment of organic waste gas, meet the design requirements and emission standards.

2. Strong adsorption capacity: Even if the composition concentration of the gas is very low at mg level, it still has adsorption capacity.Compared with similar activated carbon to improve the efficiency of 50%.

3. Wide adaptability of adsorption temperature: The adsorption capacity of zeolites is still relatively high even at higher temperature, while other adsorbents are greatly affected by temperature. Therefore, the adsorption capacity of zeolite is large at the same temperature.

4. Good regenerative temperature resistance: After adsorption and concentration by molecular sieve, the concentration factor of pollutants can be up to 15 times to 20 times. After concentration, the waste gas can be condensed and recycled or processed by high temperature combustion as required.

5. High strength: Using special skeleton materials, so that the honeycomb zeolite positive compressive strength can be more than 3Mpa, to reduce damage during transportation and installation.

Technical Index:

| Performance | Micropore | Mesopore |

| Dimensions | 100*100*100-100W 100*100*50-50W | 100*100*100-100J 100*100*50-50J |

| Mesh NO. | 100 | 100 |

| Wall Thickness | 0.4 mm | 0.4mm |

| Positive Compressive Strength | >3.0 Mpa | >3.0Mpa |

| Volume-Weight | <400 g/L | <400g/L |

| Specific Surfance Area | >900 m2//g | >900m2/g |

| Purifying Efficiency | >90% | >90% |

| Thermal Resistance | >900 degree | >900 degree |

| Lifetime | >2 years | > 2 years |