Basic Info.

Treated Air Volume

300-150000m3/H

Cooling Load

18-1820kw

Dehumidification Space

30-7500m3

Refrigerator Power

5.9-546kw

Power Supply

380V, 3p, 50Hz

Desiccant Wheel Diameter

370-1940mm

Desiccant Wheel Thickness

200mm

Transport Package

Wooden Case

Trademark

CANDID

Origin

China

HS Code

8419399090

Product Description

Industrial Desiccant Wheel Dehumidifier

Description

Dehumidification is the process of removing water from air or gases to create dry air. Air dehumidification methods commonly used in industry are divided into two main categories: cooling methods and chemical methods.

Cooling method is divided into atmospheric cooling method and compression condensation dehumidification, chemical method is divided into liquid and dry solid adsorption type.

Desiccant wheel dehumidification belongs to dry solid adsorption type, under normal circumstances, air humidity requirements in the range of 50%-70%, air dew point above 10ºC, suitable for freezing dehumidifier, air humidity requirements between 1%-50%, suitable for desiccant wheel dehumidifier, the effect is more stable.

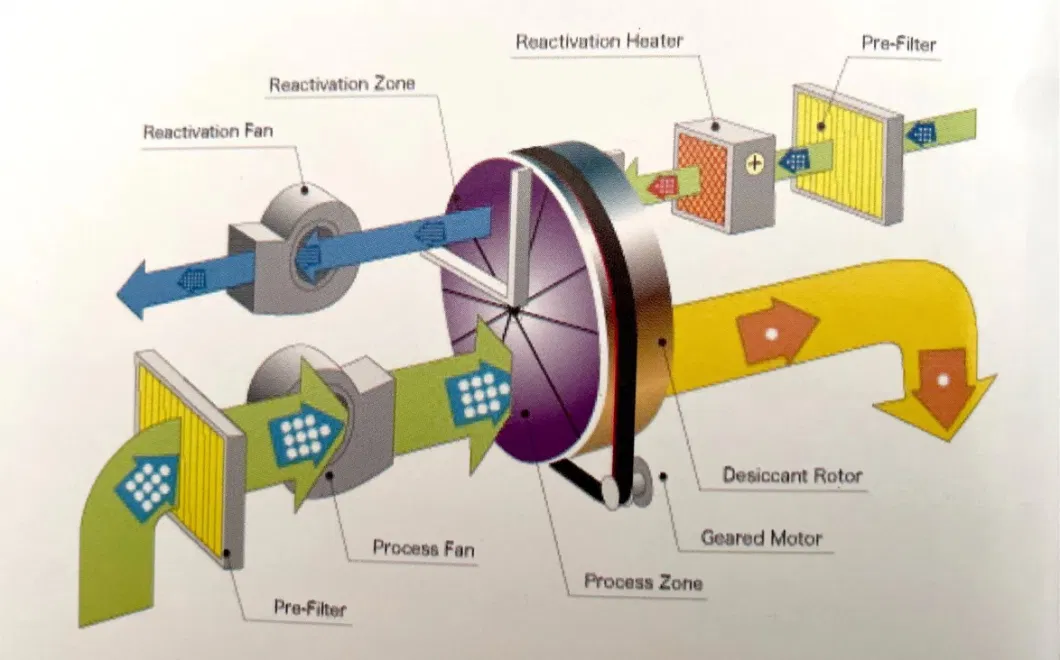

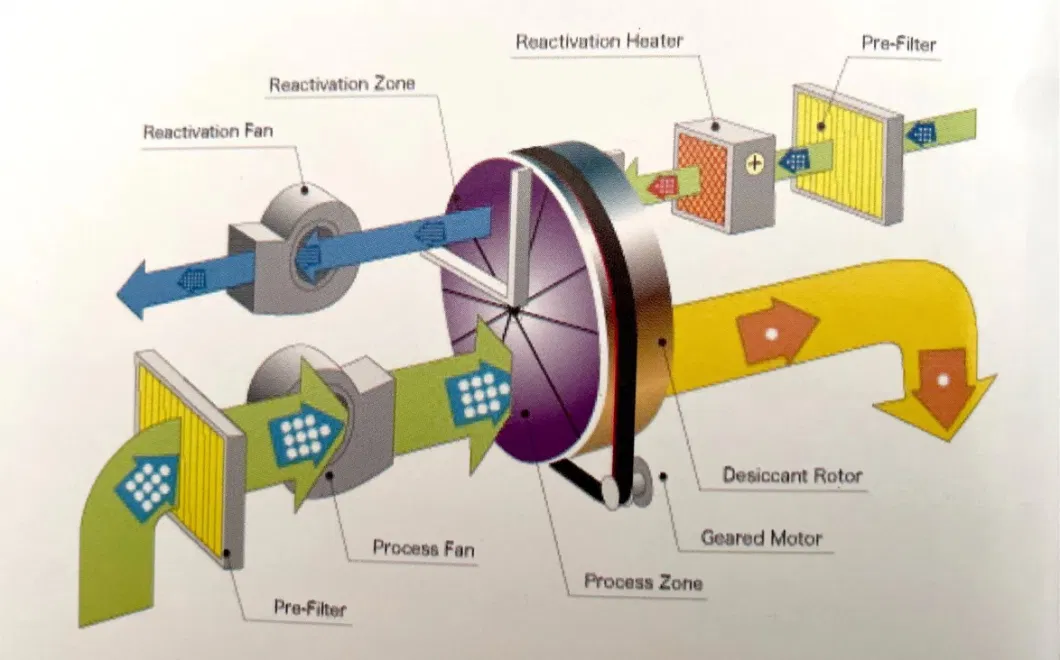

The core component of desiccant wheel dehumidifier is a rotating honeycomb type drying wheel, which is divided into two channels by sealing material. One is to deal with the 270 degree fan-shaped area of the air end; One is the 90 degree fan-shaped area at the regenerative air end. When the humid air that needs to be dehumidified enters the air end of 270 degrees treatment, the water molecules in the air are absorbed by the hygnoscopic agent in the runner and blown out into dry air; When the treatment area becomes saturated, it automatically transfers to the regeneration area and enters the process of regeneration and desorption of water. After the air in the regeneration process is heated, it enters the regeneration area. In the state of high temperature, the water molecules adsorbed by the running wheel are desorbed to the regeneration air; Due to the heat emitted in the process of water desorption, the temperature of the regenerated air decreases and becomes hot air with large moisture absorption capacity, which is discharged by the regenerated fan. The process of regeneration and dehumidification is carried out at the same time, the air is constantly dehumidified, the runner is constantly regenerated, and the cycle is repeated.

Main Technical Parameter

Description

Dehumidification is the process of removing water from air or gases to create dry air. Air dehumidification methods commonly used in industry are divided into two main categories: cooling methods and chemical methods.

Cooling method is divided into atmospheric cooling method and compression condensation dehumidification, chemical method is divided into liquid and dry solid adsorption type.

Desiccant wheel dehumidification belongs to dry solid adsorption type, under normal circumstances, air humidity requirements in the range of 50%-70%, air dew point above 10ºC, suitable for freezing dehumidifier, air humidity requirements between 1%-50%, suitable for desiccant wheel dehumidifier, the effect is more stable.

The core component of desiccant wheel dehumidifier is a rotating honeycomb type drying wheel, which is divided into two channels by sealing material. One is to deal with the 270 degree fan-shaped area of the air end; One is the 90 degree fan-shaped area at the regenerative air end. When the humid air that needs to be dehumidified enters the air end of 270 degrees treatment, the water molecules in the air are absorbed by the hygnoscopic agent in the runner and blown out into dry air; When the treatment area becomes saturated, it automatically transfers to the regeneration area and enters the process of regeneration and desorption of water. After the air in the regeneration process is heated, it enters the regeneration area. In the state of high temperature, the water molecules adsorbed by the running wheel are desorbed to the regeneration air; Due to the heat emitted in the process of water desorption, the temperature of the regenerated air decreases and becomes hot air with large moisture absorption capacity, which is discharged by the regenerated fan. The process of regeneration and dehumidification is carried out at the same time, the air is constantly dehumidified, the runner is constantly regenerated, and the cycle is repeated.

Main Technical Parameter

| No. | Item | Specification |

| 1 | Rated dehumidification | 6.2-2100kg/h |

| 2 | Treated air volume | 300-150000m3/h |

| 3 | Cooling load | 18-1820KW |

| 4 | Dehumidification space | 30-7500m3 |

| 5 | Refrigerator power | 5.9-546KW |

| 6 | Power supply | 380V, 3P, 50Hz |

| 7 | Desiccant wheel diameter | 370-1940mm |

| 8 | Desiccant wheel thickness | 200mm |