Basic Info.

Model NO.

miniRotar 500

Application

School, Hospital, Lab

Type

Separation Type

Heating Temperature Range

Room Temperature~95ºC

Temperature Control Accuracy

±1ºC

Temperature Setting and Display

Quick Setting of Knob, Digital Display of Target T

Dry Burn Protection

Automatic Power off for Dry Firing

Heating Mode

Concealed Heating

Rotation Parameter Setting and Display

TFT4.3 "Touch LCD Screen

Rotary Flask Raise and Drop Mode

Manual and Automatic Dual Mode

Timing Function

Time Can Be Set Within 0-999min. Once Times up, Th

Flask Volume

500ml

Rotation Mode

Clockwise, Counterclockwise and Clockwise Rotate T

Power off Release Vacuum Automatically

Yes

Power Supply

AC220V 50/60Hz

Transport Package

Wooden Pallet

Trademark

AUWII

Origin

China

HS Code

8419409090

Production Capacity

50000

Product Description

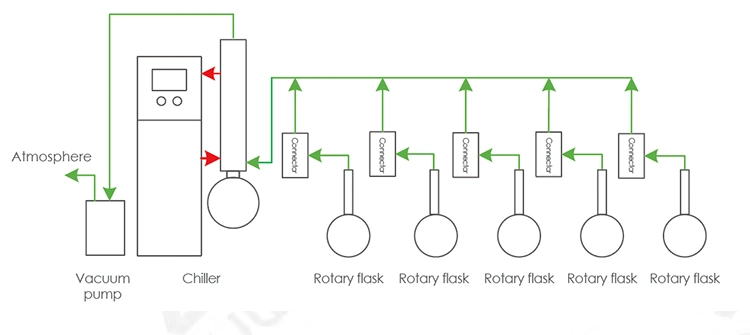

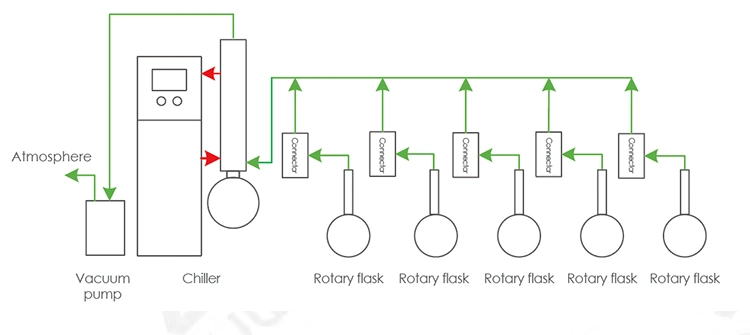

Array rotary evaporator is an innovative pre-processing equipment that can simultaneously concentrate and process multiple samples. It consists of multiple miniRotar rotary evaporator units, a vacuum system, and a solvent condensation recovery system. It can greatly improve the experiment while realizing multiple sample processing. Room space utilization.

○ MiniRotar designs longitudinal rotating axis innovatively, reducing the product width to 25cm,

which is one third of traditional rotary evaporator. 1.8m standard fume hood can put up to 5 miniRotars, fully save the fume hood space.

Array Combination -- Improves Efficiency

○ Special connector design can keep multiple units working in parallel, sharing one Vacuum system and one Recovery system. Highly recommended on processing multiple samples at the same time to improve work efficiency.

○ Each miniRotar can set it's own temperature, rotation speed and time, and can independently lift and lower the flask. MiniRotar 500s equips an independent quick release vacuum button, which can release the vacuum independently without interfering other rotary evaporator units.

Timing of evaporation -- Less Attention

○ MiniRotar500s can setting it's working time according to users experience. Once time is up, miniRotar500s will automatically stop rotating and release vacuum, lift the flask to part from water bath, and automatically stop sample evaporation and concentration.

Double Protection -- Avoid Contamination

○ MiniRotar is equipped with a backflow prevention connector, which can avoid contamination of samples and ensure the accuracy of analysis results.

Vacuum pump

Vacuum controller

Chiller

The miniRotars can work simultaneously, or operate independently. Each can set it's own temperature, adjust speed, release vacuum etc., without interfering other rotary evaporator units.

Extreme mini -- Saves Space

○ MiniRotar designs longitudinal rotating axis innovatively, reducing the product width to 25cm,

which is one third of traditional rotary evaporator. 1.8m standard fume hood can put up to 5 miniRotars, fully save the fume hood space.

Array Combination -- Improves Efficiency

○ Special connector design can keep multiple units working in parallel, sharing one Vacuum system and one Recovery system. Highly recommended on processing multiple samples at the same time to improve work efficiency.

○ Each miniRotar can set it's own temperature, rotation speed and time, and can independently lift and lower the flask. MiniRotar 500s equips an independent quick release vacuum button, which can release the vacuum independently without interfering other rotary evaporator units.

Timing of evaporation -- Less Attention

○ MiniRotar500s can setting it's working time according to users experience. Once time is up, miniRotar500s will automatically stop rotating and release vacuum, lift the flask to part from water bath, and automatically stop sample evaporation and concentration.

Double Protection -- Avoid Contamination

○ MiniRotar is equipped with a backflow prevention connector, which can avoid contamination of samples and ensure the accuracy of analysis results.

Rotary evaporator

| Technical parameter | miniRotar500 | miniRotar500s |

| Heating temperature range | Room temperature~95ºC | Room temperature~95ºC |

| Temperature control accuracy | ±1ºC | ±1ºC |

| Temperature setting and display | Knob to quickly set the target temperature and real-time temperature digital display | Knob to quickly set the target temperature and real-time temperature digital display |

| Dry burn protection mode | Automatic power off for dry burning | Automatic power off for dry burning |

| heating method | Concealed heating | Concealed heating |

| Rotation axis direction | Portrait setting | Portrait setting |

| Rotation parameter setting and display | TFT4.3Inch touch LCD screen | TFT4.3Inch touch LCD screen |

| Rotating screen lifting mode | Manual and automatic dual mode | Manual and automatic dual mode |

| Timing function | N/A | YES |

| (The time can be set within 0-999min. When the time is reached, the rotating bottle stops rotating. | ||

| Automatically lift out of the heating water bath and release the vacuum at the same time, the sample stops evaporating) | ||

| Maximum volume of rotating bottle | 500mL | 500mL |

| Rotating bottle interface specifications | standard 24/29 interface | standard 24/29 interface |

| Rotation mode | clockwise rotation | Three modes: clockwise counterclockwise clockwise and counterclockwise alternately |

| Vacuum release method | Manual switch valve to release vacuum | Shortcut button to release vacuum |

| (When multiple groups are used in parallel, the vacuum of one group of rotary evaporators is released without affecting the normal operation of other rotary evaporators) | ||

| Turn off the power and automatically release the vacuum | N/A | YES |

| Sample observation light | USB interface led light | USB interface led light |

| Suction port | φ10mm Pagoda connector | φ10mm Pagoda connector |

| Communication Interface | N/A | RS485 |

| voltage | AC220V 50/60Hz | AC220V 50/60Hz |

| input power | 700W | 700W |

| Dimensions(mm) | deep 530×width 250×high 520 | |

Vacuum pump

| Technical parameter | eV35 | eV35s |

| Vacuum pump type | High performance diaphragm vacuum pump | German original diaphragm vacuum pump |

| Diaphragm material | PTFE | PTFE |

| Pump head material | PTFE | PTFE |

| Ultimate vacuum | 8mbar | 8mbar |

| Maximum pumping speed | 35L/min | 34L/min |

| Pneumatic interface | φ10mm Pagoda connector | φ10mm Pagoda connector |

| Vacuum gauge | Pointer vacuum gauge | Pointer vacuum gauge |

| Vacuum control valve | Precision hand-tightened vacuum control valve | Precision hand-tightened vacuum control valve |

| Vacuum adjustment range | -0.1-0Mpa | -0.1-0Mpa |

| voltage | AC220V 50/60Hz | AC220V 50/60Hz |

| input power | 240W | 245W |

| Maximum load | Can be equipped with up to 6 sets of mini rotary evaporation units | Can be equipped with up to 6 sets of mini rotary evaporation units |

| Dimensions(mm) | deep 350×width 170×high 350 | |

Vacuum controller

| Technical parameter | eC35 | eC35s |

| Vacuum degree control range | 20-1050mbar | 10-1050mbar |

| Vacuum setting accuracy | 1mbar | 1mbar |

| Vacuum degree control accuracy | 5mbar | 2mbar |

| Display screen | 5 inch TFT touch screen | 5 inch TFT touch screen |

| Vacuum control order | 5 | 5 |

| Material contact part material | 316 stainless steel | PEEK,PTFE,Perfluoroether rubber,PFA |

| Vacuum pump power control | N/A | Can control the start/stop of the vacuum pump |

| Communication Interface | N/A | RS485 |

| Pneumatic interface specifications | 316 stainless steel φ10mm Pagoda connector | PEEK φ10mm Pagoda connector |

| voltage | AC100-230V,50/60Hz | AC100-230V,50/60Hz |

| input power | 50W | 50W |

| Dimensions(mm) | deep 240×width 160×high170 | |

Solvent Recovery Unit

Glass condenser

| Specification | eSR220s | eSR320s |

| Condense stage | Three stages | Three stages |

| Lowest temperature | -20ºC | -20ºC |

| Collection bottles | One | Two |

| Collection bottle Volume | 1000ml | 3000ml |

| Condensing pipeline ring material | Special material (Resistance to chloride) | Special material (Resistance to chloride) |

| Inlet interface specification | PEEK φ10mm Pagoda-Shape Connector | PEEK φ13mm Pagoda-Shape Connector |

| Outlet interface specification | PEEK φ10mm Pagoda-Shape Connector | PEEK φ12mm Pagoda-Shape Connector |

| Power supply | AC220V 50Hz | AC220V 50Hz |

| Overall dimensions | L(510mm)W(240mm)H(682mm) | L(510mm)W(340mm)H(710mm) |

Glass condenser

| Technical parameter | GL1000 |

| Material | Borosilicate glass |

| Suction port | φ10mm Pagoda connector |

| Waterway interface | φ10mm Pagoda connector |

| Collection bottle volume | 1000ml |

| Condenser tube surface area | 0.2 m2 |

| a fixed way | V35,V35sVacuum pump and T series Cooling circulating water machines have GL1000 installation interface, Can be easily suspended and fixed |

Chiller

| Specification | T4 | T4α | T4β |

| Temperature Range | 5-35ºC | -10-35ºC | -20-35ºC |

| Temperature Stability | ±0.1ºC | ±0.1ºC | ±0.1ºC |

| Cooling Capacity | 1600W @20ºC | 1500W @20ºC | 1200W @20ºC |

| Reservoir Volume | 8L | 8L | 8L |

| Overall dimensions | 490×246×790 | 490×246×790 | 490×246×790 |

| Specification | T3 | T3α | T3β |

| Temperature Range | 5-35ºC | -10-35ºC | -20-35ºC |

| Temperature Stability | ±0.1ºC | ±0.1ºC | ±0.1ºC |

| Cooling Capacity | 1200W @20ºC | 1000W @20ºC | 800W @20ºC |

| Reservoir Volume | 7L | 7L | 7L |

| Overall dimensions | 460×210×660 | 460×210×660 | 460×210×660 |

| Specification | T2 | T2α | T2β |

| Temperature Range | 5-35ºC | -10-35ºC | -20-35ºC |

| Temperature Stability | ±0.1ºC | ±0.1ºC | ±0.1ºC |

| Cooling Capacity | 700W @20ºC | 600W @20ºC | 500W @20ºC |

| Reservoir Volume | 5L | 5L | 5L |

| Overall dimensions | 410×210×560 | 410×210×560 | 410×210×560 |

| Specification | T1 | T1α | - |

| Temperature Range | 5-35ºC | -10-35ºC | - |

| Temperature Stability | ±0.1ºC | ±0.1ºC | - |

| Cooling Capacity | 450W @20ºC | 300W @20ºC | - |

| Reservoir Volume | 3L | 3L | - |

| Overall dimensions | 350×176×550 | 350×176×550 | - |