Basic Info.

Mechanical Principle

Vacuum

Performance

Vacuum Filtration, Dehydration, Degas

Color

Blue, White, Green, Yellow, etc.

Weight

1060 Kgs

Flow Rate

6000 L/Hr

Working Vacuum Degree

-0.08 ~ -0.099 MPa

Filtration Accuracy

1 Micron

Vacuum Pumps

2 Stage (Rotary Vacuum Pump+Booster Roots Pump)

Power Supply

380V, 50Hz, 3phase (or as Per Request)

Delivery Time

15 Days

Heating Power

90kw

Total Power

105kw

Application Oil

Oil in Transformer, Inductor, Circuit Breaker

Warranty Period

2 Years

Certificates

ISO, CE, SGS

After-Sales Service

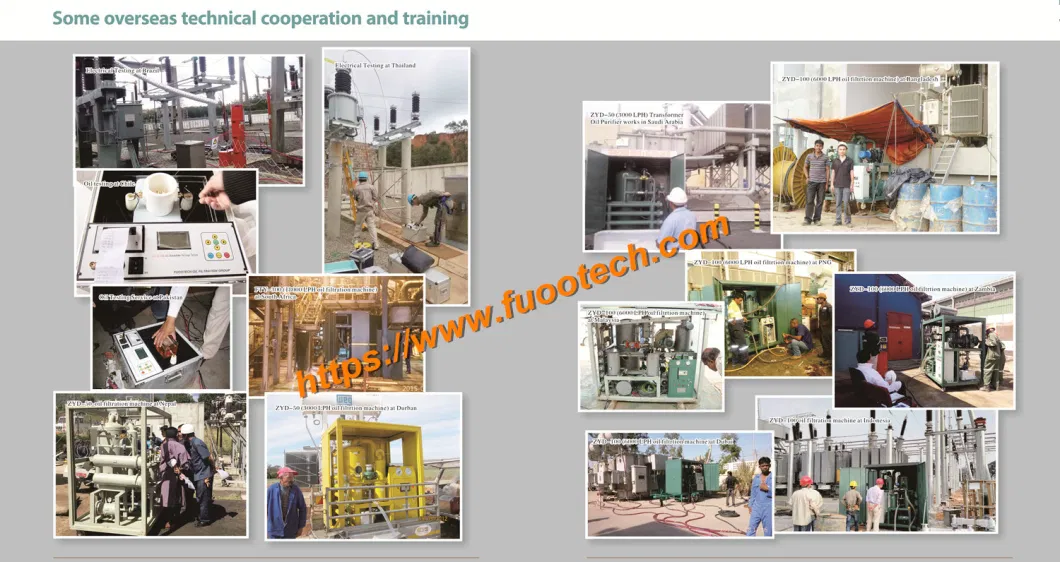

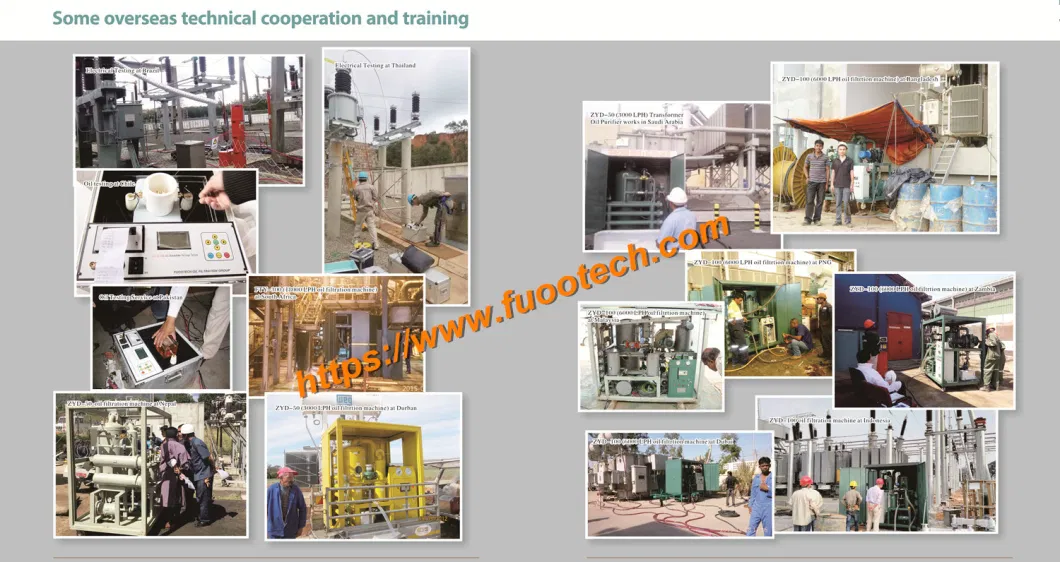

Video Online Technical Support, Field Training

Structure Material

Carbon Steel

Transport Package

in Exportation Plywood Case

Specification

1750*1450*1920mm

Trademark

FUOOTECH

Origin

Chongqing, China

HS Code

8421299090

Production Capacity

5000 Sets/Year

Product Description

Brief Introduction:

FUOOTECH Series ZYD-T Double-stage High Vacuum Transformer Oil Filtration Machine is a ultra high vacuum oil dehydration system for Dielectric Transformer Oil Purification and Oil Filtering. This transforemr oil filtration equipment can quickly remove water, trace water, gas, particles as well as acetylene, hydrogen, methane and other harmful ingredients from oil effectively to improve oil's dielectric strength, effectively making sure electric equipment working safely and normally. It's particularly suitable for treating high-grade transformer oil, super-voltage transformer oil and new transformer oil. It can be used for filtration of more than 110V substation live line work on-site. Meanwhile, it can be used as independent vacuum resource with functions of vacuum drying and vacuum oiling.

ZYD-T Series Transformer Oil Degassifier using advanced T-Shape Vacuum Chamber which has much larger evaporation area than normal vertical vacuum chamber, so it can degas and dehydration much faster with higher efficiency.

Features:

Features:

Note: 1. The dimension and weight will be changed with changing of technical specs.

2. All the specs can be customized according to client's requirements.

Packing & Delivery:

Logistics & Payment:

Some of our main clients and partners:

About Us:

FUOOTECH Series ZYD-T Double-stage High Vacuum Transformer Oil Filtration Machine is a ultra high vacuum oil dehydration system for Dielectric Transformer Oil Purification and Oil Filtering. This transforemr oil filtration equipment can quickly remove water, trace water, gas, particles as well as acetylene, hydrogen, methane and other harmful ingredients from oil effectively to improve oil's dielectric strength, effectively making sure electric equipment working safely and normally. It's particularly suitable for treating high-grade transformer oil, super-voltage transformer oil and new transformer oil. It can be used for filtration of more than 110V substation live line work on-site. Meanwhile, it can be used as independent vacuum resource with functions of vacuum drying and vacuum oiling.

ZYD-T Series Transformer Oil Degassifier using advanced T-Shape Vacuum Chamber which has much larger evaporation area than normal vertical vacuum chamber, so it can degas and dehydration much faster with higher efficiency.

- Advanced Duplex 3D stereo-evaporation, efficient oil film sprayer, giving high effective dehydration and degas, increasing separating size and separating time to ensure the dry-level and dielectric strength improving greatly.

- Double-stage vacuum system, high vacuum pressure and high flow rate, strong power of vacuum evacuating.

- Advanced multi-stage precision filtration system, stainless steel materials filtration combined with molecular adsorption technologies

- Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

- Double-infrared liquid level sensor, pressure protective system to ensure machine operation easy and safely.

- Especially applied to vacuum oiling and drying (Hot Oil Circulation / on-site Drying) for power transmission equipments which are over 110KV.

- Adopt interlocked protection system, which connects oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leakage and electricity leak.

- Low maintenance cost and time, simple operation and maintenances.

- Can be made in mobile trailer and fully enclosed type, fully automatic type with PLC, explosion-proof type, etc… according to actual working condition/requirements.

Technical Specification:

| Parameters | Model Unit | ZYD-T-30 | ZYD-T--50 | ZYD-T--100 | ZYD-T--150 | ZYD-T--200 | ZYD-T--250 | ZYD-T--300 |

| Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 |

| Working Vacuum Degree | MPa | -0.08 ~ -0.099 | ||||||

| Working Discharge Pressure | MPa | ≤ 0.3 | ||||||

| Temperature Control Range | ºC | 20 ~ 80 | ||||||

| Operation Temperature | ºC | 40 ~ 70 (65ºC is best) | ||||||

| Power Supply | 380V, 50Hz, 3 phases (or as per your requirements) | |||||||

| Working hours without Trouble | Hour | 4000 | ||||||

| Continuous Working Hours | Hour | 150 | ||||||

| Ambient Temperature | -25 ~ 55ºC | |||||||

| Working Noise | dB(A) | 65 ~ 90 | ||||||

| Heating Power (adjusted available) | KW | 30 | 48 | 60 | 90 | 135 | 150 | 180 |

| Total Power | KW | 35.5 | 52.5 | 68 | 105 | 154 | 165 | 208 |

| Inlet/Outlet | mm | φ25 | φ32 | φ42 | φ50 | φ50 | φ60 | φ60 |

| Weight | Kg | 600 | 700 | 1050 | 1150 | 1450 | 1600 | 1950 |

| Dimension | mm | 1380×1020×1760 | 1610×1250×1950 | 1750×1350×2150 | 1850×1400×2200 | 1950×1500×2300 | 2050×1600×2400 | 2200×1750×2550 |

| After Filtration | Moisture (Water Content) ≤ 5 PPM | |||||||

| Gas Content ≤0.01% (Vol) | ||||||||

| Impurities Degree (Filtration precision) ≤ 1 micron (no free carbon) | ||||||||

| Breakdown Voltage (Dielectric Strength) ≥70 KV | ||||||||

| Flash Point ≥145ºC | ||||||||

| Cleanliness ≤NAS 1638 Grade 6 | ||||||||

2. All the specs can be customized according to client's requirements.

Packing & Delivery:

Logistics & Payment:

Some of our main clients and partners:

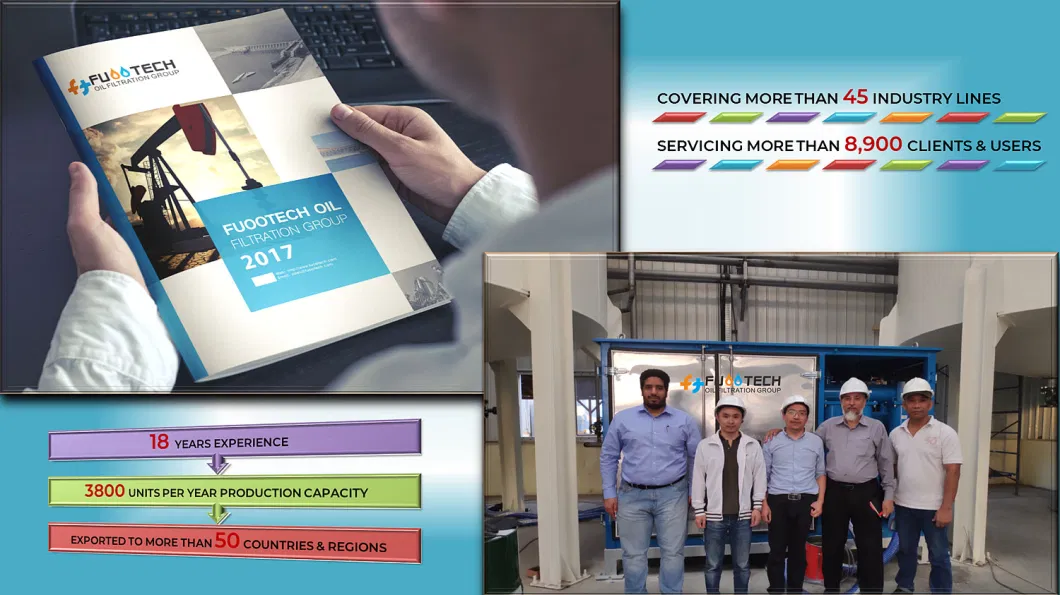

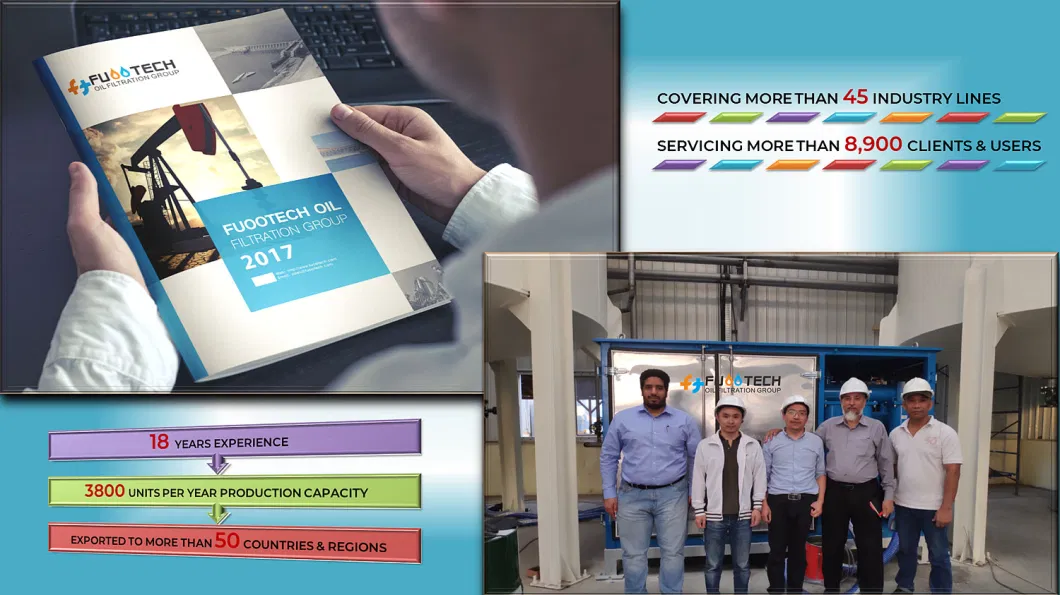

About Us: