Basic Info.

Power(Kw)

2.2 Kw

Capacity (Kg)

12 Kg

Blower Power(W)

0.05 W

Model

20u

Drying Blower

0.05kw

Feeding Blower

0.75kw

Ari Inlet Pipe

2inch

Air Return Pipe

1.5inch

Transport Package

Wooden Support

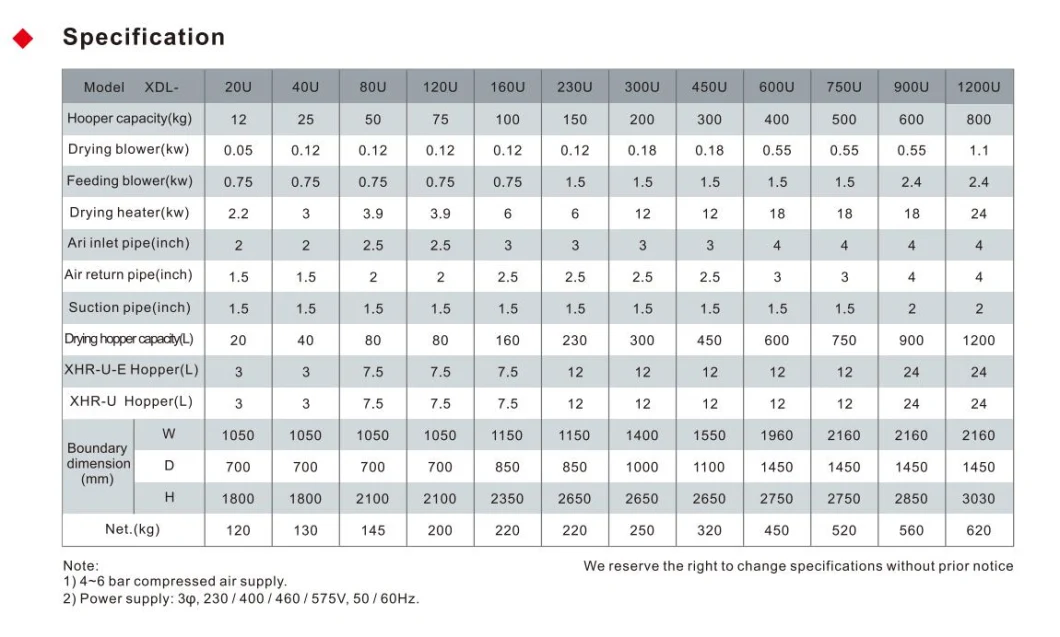

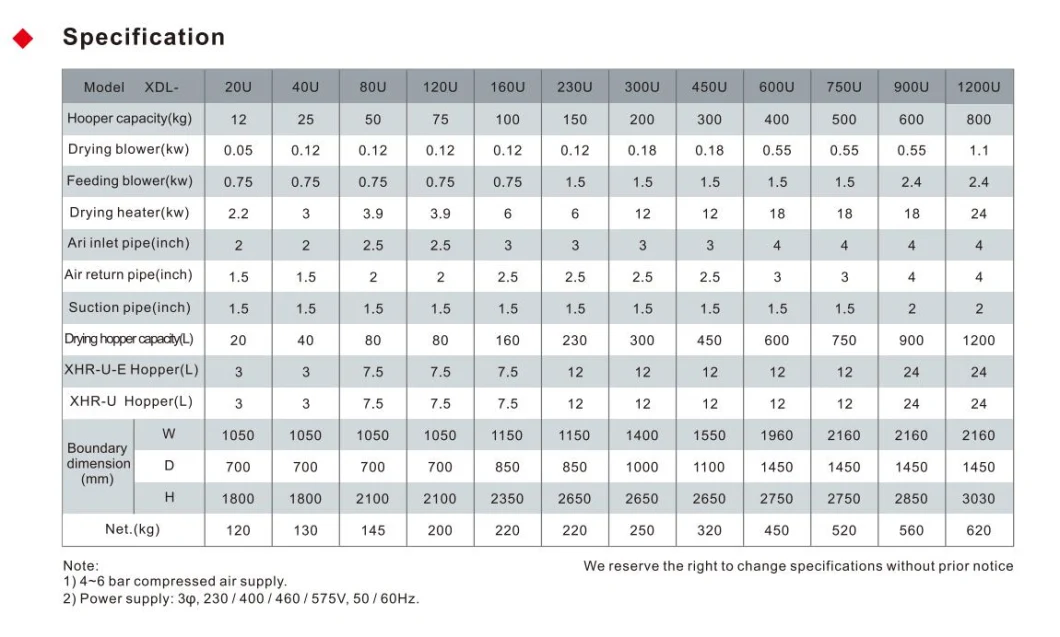

Specification

1050*700*1800mm

Trademark

manvac

Origin

China

HS Code

8419399090

Production Capacity

5000000pieces/Year

Packaging & Delivery

Package Size

120.00cm * 85.00cm * 200.00cm

Package Gross Weight

32.000kg

Product Description

Two-ln-One Dryers

Drying: based on the principle of water high temperature gasification, moisture of material wouldbe blown away by high pressure air from blower ter being high temperature gasified. A part of airwith moisture discharges through filter of moisture outlet; most part of air are recyclable afterbeing filtered through return air pipe.Conveying: suction force of high pressure blower makes avacuum inside hopper also produces differential pressure between hopper and outer space. Withthe common force of differential pressure and continuous suction, materials and air mixture wilbe sucked into hopper. Due to the filter block of hopper, materials will be ccumulated in hopperand the air is expelled from air outlet. Double-stage conveying is mainly accomplished by shiftingthree way valve of suction machine to control suction return circuit. Heatless regeneration; Thecompressed air after passing through inlet filter 11 enters into dry barrel 1 (or dried barrels 2)through pneumatic control valve 1. Then it make absorption dry with desiccant bed layer, andater exist from non-return valve 9 (or 10) , finally exist from the outlet to dry and purify air. A pariof dry air (about 15%) enters dry barrel 2 (or dried barrel 1) through current limitation pipe 8 toblow and regenerate desiccants with saturated water, then air passes through pneumatic controlvalves 1 to exist out of muffler 7. Drying barrel1 , 2 work alternately to regenerate.

FEATURES AT A GLANCE

1.MVL-U integrates autoloading and drying into one unit.

2.Adopts microprocessor and P.l.D controlsystem to accuratelycontroldrying temperature.

3.Hopper are made of stainless steelto eliminate materialcontamination.

4.Full functionalalarming system can immediately show faults.

BOUNDARY DIMENSION

CERTIFICATE

SUCCESSFUL PROJECT