- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Company Profile

Basic Info.

Product Description

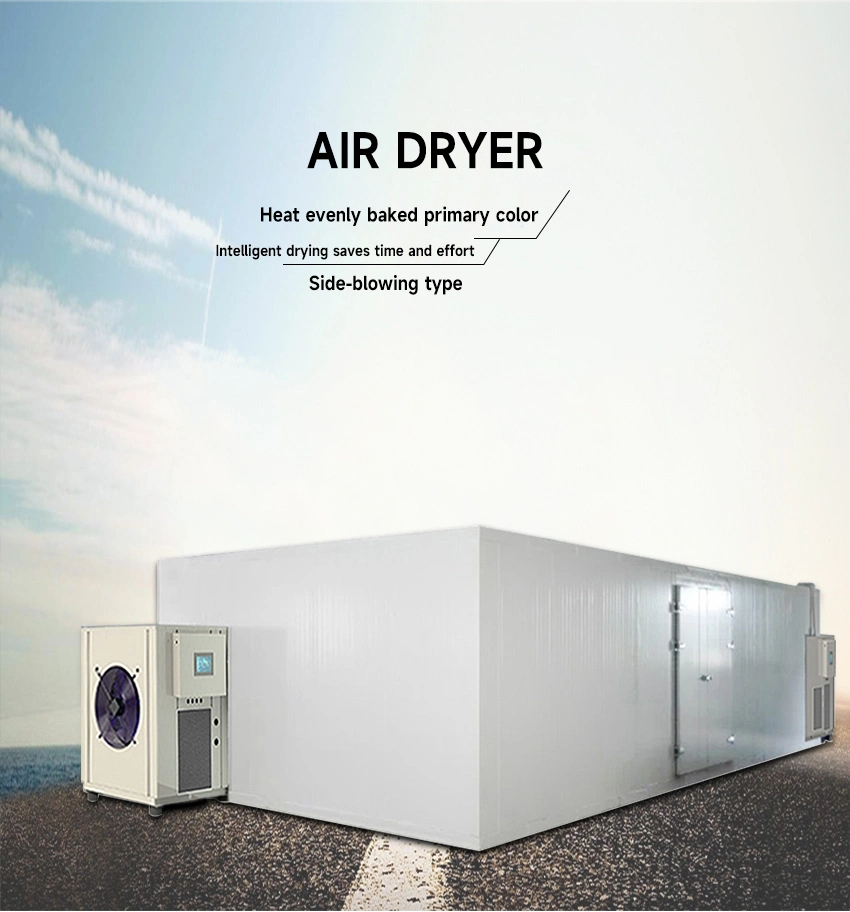

Air dryer heat evenly baked primary color intelligent drying saves time and effort

Advantages:

1.Repeated heat recovery:the hot and cold air is flushed back to the main engine after dehumidification and then heated back to the drying room

2.Higher heating effect:high power and high quality compressors guarantee faster and more efficient cooling/heating

3.More uniform drying:more uniform drying 360 degrees no dead angle drying materials inside and outside synchronous drying

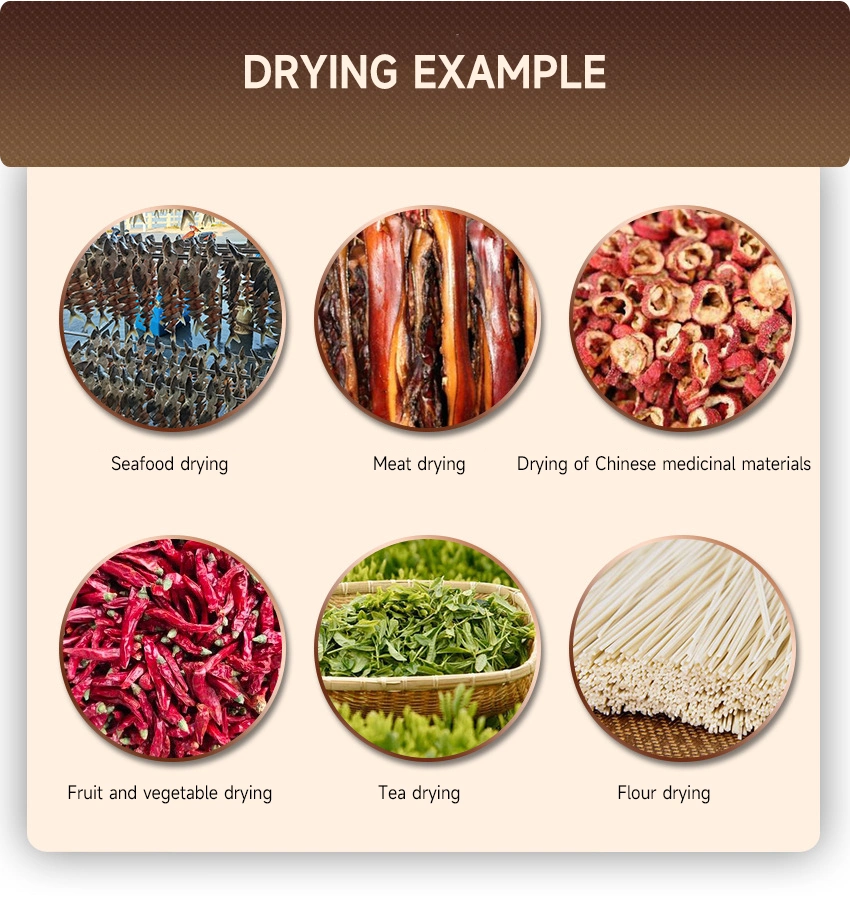

4.Wide range of drying products:such as seafood, meat, herbs, fruits and vegetables, tea, flour and so on.

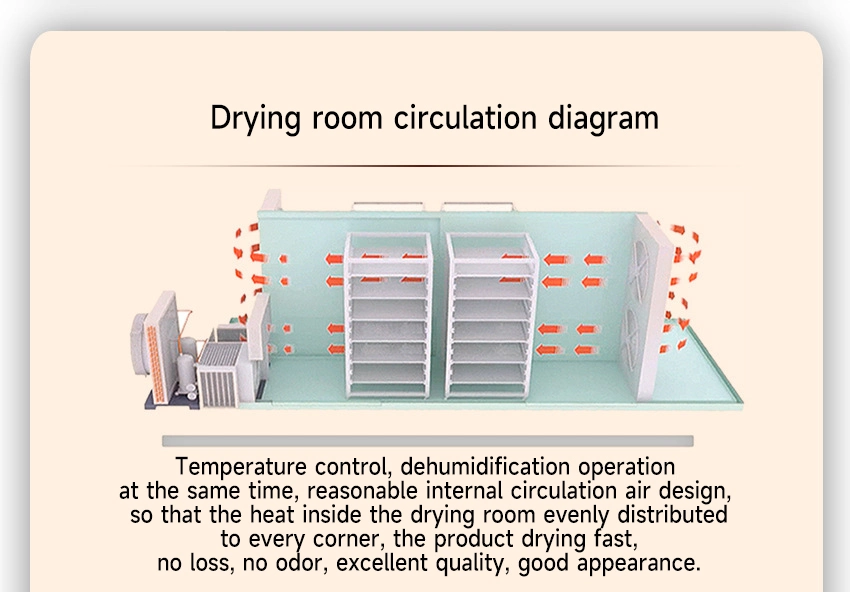

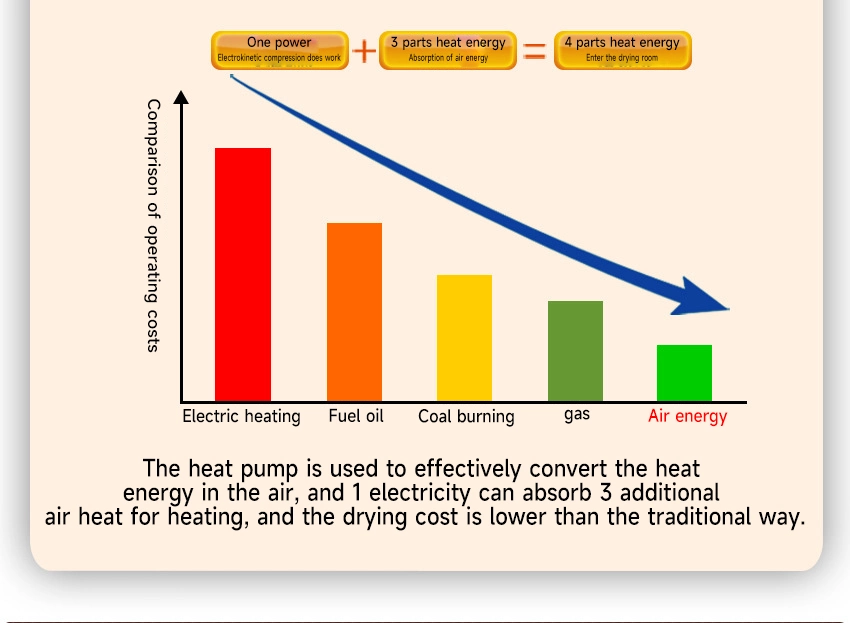

5.Dryer core components situation:according to different models, the dryer equipment can produce 400-1000 kilograms of dry goods per day;drying room temperature control, dehumidification operation at the same time, reasonable internal circulation air design, so that the heat inside the drying room evenly distributed to every corner, the product drying fast, no loss, no odor, excellent quality, good appearance,the heat pump is used to effectively convert the heat energy in the air, and 1 electricity can absorb 3 additional air heat for heating, and the drying cost is lower than the traditional way.

Product details:

1.Strong performance compressor compression system using the united states valley wheel compressor, strong performance, more suitable for long-term stable operation in harsh environment, equipment has over current protection, lack of phase protection and other multiple safety protection, effectively ensure the service life of equipment.

2.High temperature and high humidity fan circulation system adopts high temperature and high humidity resistance axial flow fan and circulation fan, high performance, high air volume, effectively increase air flow, rapid heat exchange, strong dehumidification, motor aluminum pure copper winding, waterproof and durable.

3.Strong anti-electromagnetic interference, intelligent electronic control, automatic regulation, to ensure the safe and stable operation of the unit.

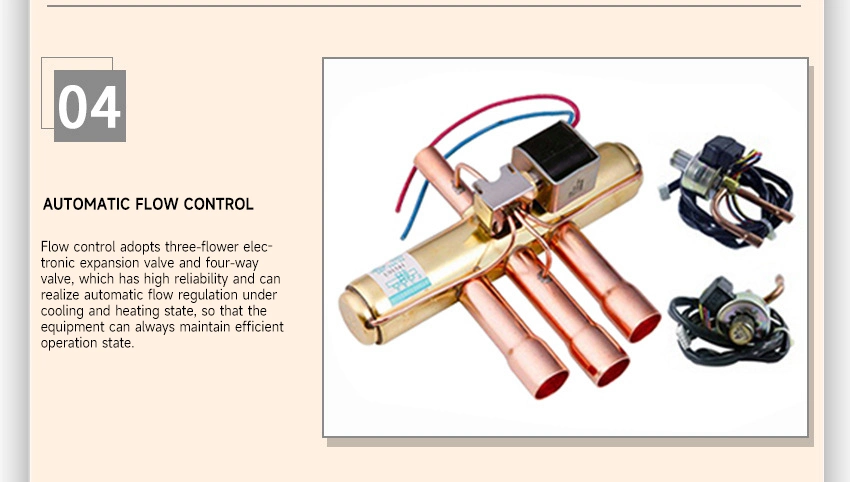

4.Automatic flow control the flow control adopts three-flower electronic expansion valve and four-way valve, which has high reliability and can realize automatic flow regulation under cooling and heating state, so that the equipment always maintains efficient operation state.

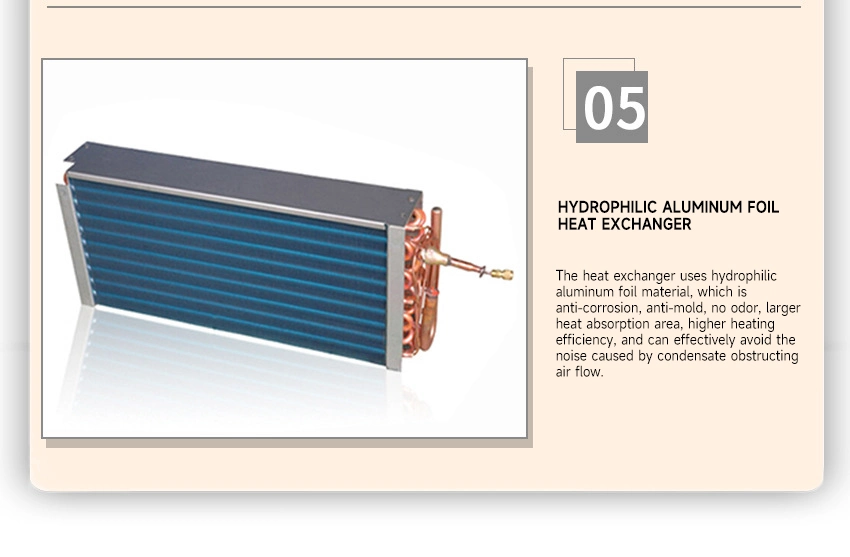

5.Hydrophilic aluminum foil heat exchanger the heat exchanger uses hydrophilic aluminum foil material, anti-corrosion, anti-mold, no odor, larger heat absorption area, higher heating efficiency, but also effectively avoid the noise caused by condensation water obstructing air flow.

| Drying room model | 2XL-5HGK20 | 2XL-5HGK28 | 2XL-5HG+K38 | |||

| Dryer model/number | XL-3P | 2 | XL-5P | 2 | XL-6P | 2 |

| Overall appearance (mm) | 8250*2100*2400 | 8950*2600*2400 | 10720*2600*2400 | |||

| Net size (mm) | 4900*1900*2200 | 5600*2400*2200 | 7200*2400*2200 | |||

| Drying Room Body(mm) | 6500*2100*2400 | 7200*2600*2400 | 9000*2600*2400 | |||

| Fan rack (width " height " quantity) | 1150*2200 | 2 | 1650*2200 | 2 | 1450*2200 | 2 |

| Fan (Model'Quantity) | 3-0.25/380V | 12 | 3-0.25/380V | 12 | 3-0.25/380V | 16 |

| Compartment (length' width) | 4900*2200 | 5600*2200 | 7200*2200 | |||

| Cart size/quantity | 1065*810*1850 | 8 | 1610*1070*1750 | 6 | 1610*1070*1750 | 8 |

| Size/quantity of baking pan | 1000*800*50 | 20 | 1000*800*50 | 80 | 1000*800*50 | 240 |

| Drving Material Reference (kg) | 600 | 1000 | 1250 | |||

| Power I Average power consumption | 21.1kw |8 degrees \ hour | 24.7kw |11 degrees \ hour | 27.12kw |13 degrees \hour | |||